CALC4XL PRODUCT COSTING SOFTWARE

Safe, understandable, stand-alone and yet fully Excel-integrated.

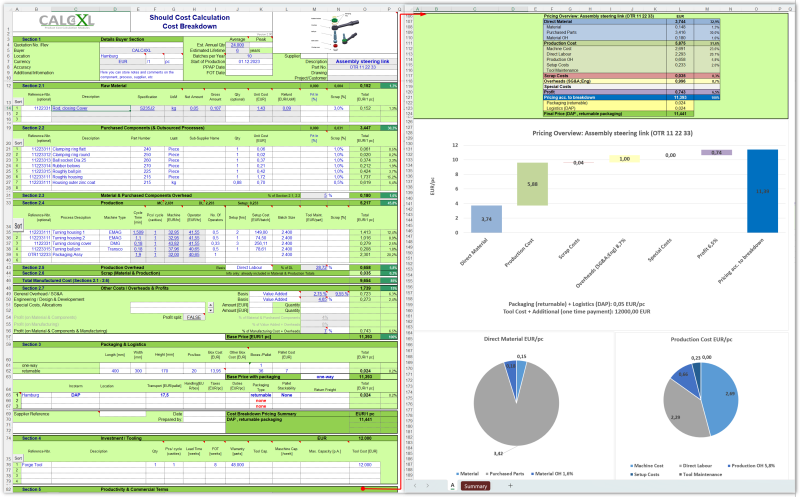

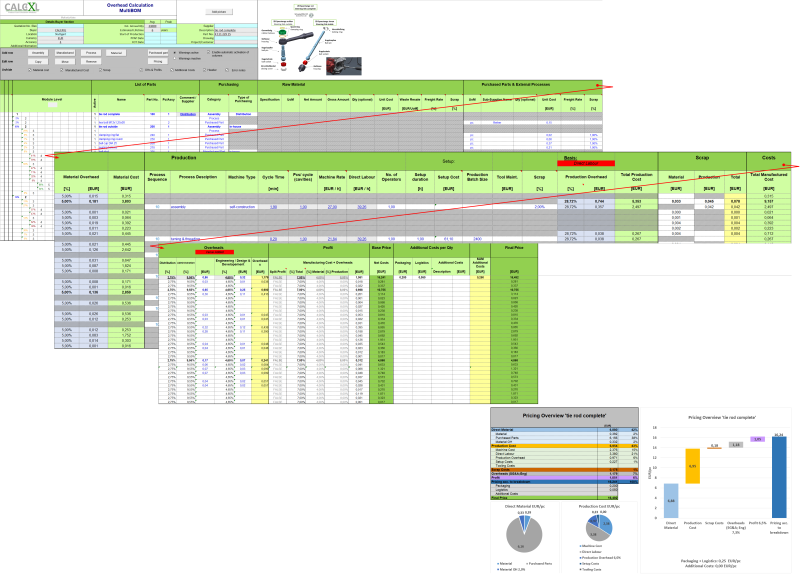

CALC4XL is a solution to produce a product cost calculation, quotation calculation, design change or cost break down in a transparent and reproducible way.

How much may a component cost, how much does it cost in the best cost country or in the own production? How can I price a design change? What are the cost drivers? These questions, which seem easy at first glance, often cannot be answered validly. There is often a lack of comparative data and expert knowledge to plausibilize a supplier offer or a new technology without great effort.

With the CALC4XL software, purchasers and distributors are strengthened for upcoming price negotiations, carry out effective supplier benchmarking and convince with comprehensible product calculations. The comprehensible calculation schemes, manufacturing process calculators and worldwide benchmark data offer the development department as well as production an efficient cost driver and thus design optimization. Thus, the controlling department has a company-wide comprehensible product cost calculation, which can be modified at any time via the familiar Excel application, docked to your own Excel solutions and effectively saved without additional application complexity.

The story - the goal

Years of experience in costing on the user side as well as on the software manufacturer side have always led us to think about the optimal solution for a product cost calculation. The complexity of the software on the market in application and modification, the lack of integration into the existing software landscape and the compulsion to abandon own, existing (e.g. Excel) solutions has always baffled us.

... individually adaptable and expandable at any time, but

... secured by a password-based rights and role system,

... integrating any existing solutions, but

... standardized and centrally controlled if required,

... understandable and directly comprehensible for third parties, so that

... able to be used internally as well as externally for costing exchange, cost discussion or even open-book costing, i.e. but also

... not excluding external users without the specific software,

... consistently underpinned with a uniform costing database of expert knowledge (worldwide benchmark data, manufacturing process computers, etc.),

... embedded in the software landscape by means of proven interfaces,

... accessible everywhere for every authorized person,

... without dependency on the provider, i.e. own data and calculations should exist even after switching off the system,

... and ALL without additional application complexity!

We asked ourselves, why previous solutions always reprogrammed Excel with reduced functionality and significantly increased complexity. So we combined the above requirements with our accumulated knowledge, process logics and data from cooperations, universities and state statistics offices and realized a software that acts independently, but is directly, transparently integrated into Excel. The enormous market response from partners who have seen our software in operation prompted us to professionalize the software and now offer it to everyone at a reasonable price.

CALC4XL enables you to discuss costs knowledgeably and not only about price budgets by calculating confidently - whether independently for the department, across departments, company-wide or even just-in-time on-site with the cooperation partner, supplier, customer.

It is important to us that you become part of our costing network and receive expert support in your projects. For this purpose, we offer workshops, project and costing support as well as numerous contacts to other cost estimators.

The Excel approach

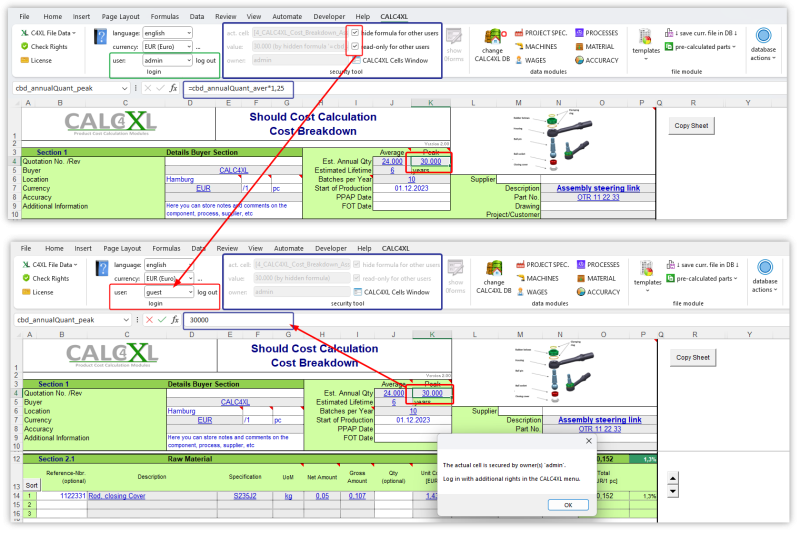

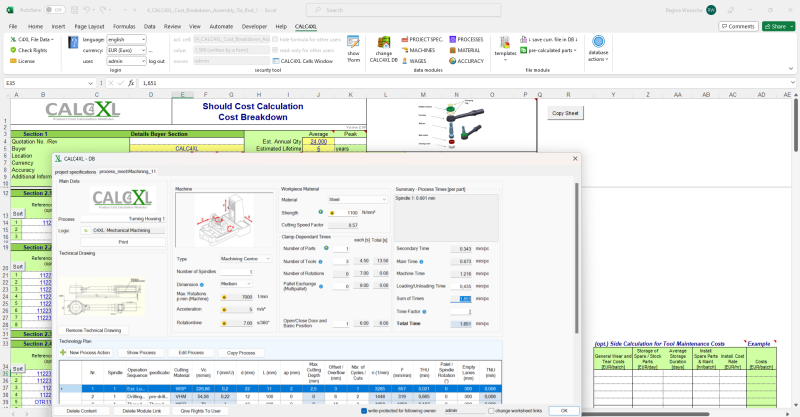

- CALC4XL is a stand-alone software, which is nevertheless transparently integrated into Excel via a so-called add-in.

- As shown in the picture, you get a new "CALC4XL" menu after the installation in Excel, with which you can completely control CALC4XL.

- This gives you no additional IT hurdles (ready to use in 10 seconds) and most importantly no additional application complexity.

- By means of the free CALC4XL viewer, even employees and external parties without a CALC4XL license can access your calculations. The familiar Excel application thus enables the exchange across all borders up to an open-book calculation.

- Use, modify and extend our and your Excel cost calculation templates with your Excel know-how or just integrate the cost modules (wage, machine, manufacturing process calculator, worldwide data sets, ...) into your existing Excel solution (see below "The Integration").

- And if you ever want to switch off CALC4XL, keep all your data, calculations and custom templates in the familiar Excel environment.

The costing contents

- full cost benchmark database with annual update:

- uniform, differentiated database

- over 400 country data sets with area rate, energy costs, calcul.

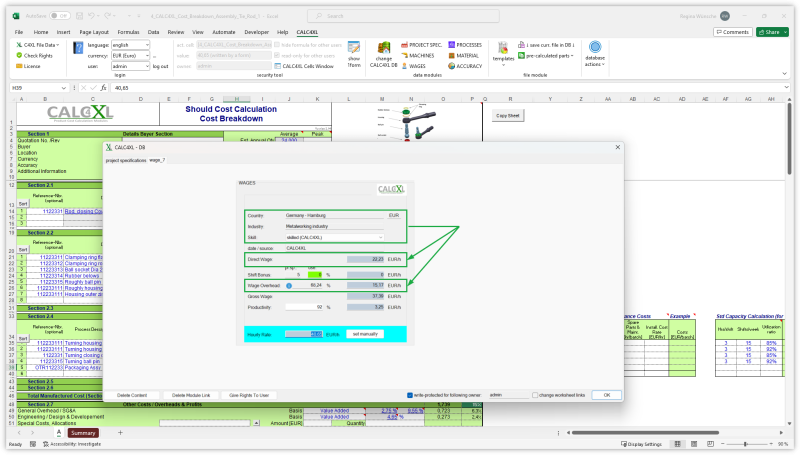

- over 70,000 overhead rates for all indirect cost areas such as material, production, sales, administration, logistics and development costs > over 2,500 international industrial park wage rates (direct wage, employer's contribution), broken down into three qualification levels

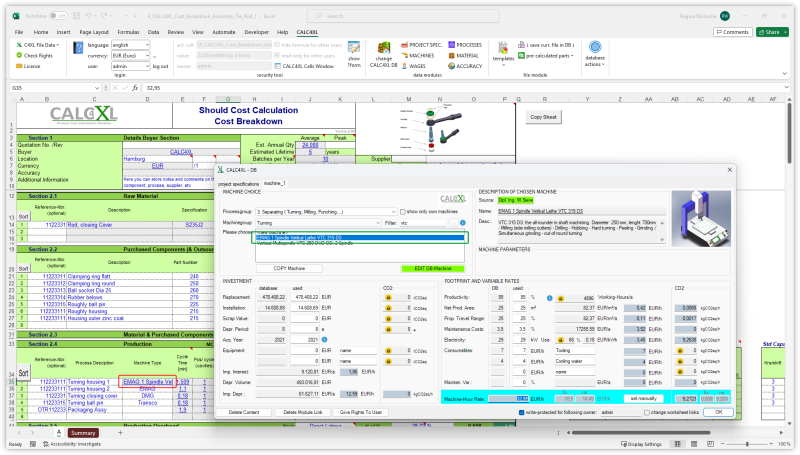

- over 1,500 machine records for all common production technologies with technical, machine-specific and business data such as name, description, investment, installation costs, floor space, energy costs, maintenance and machine-specific e.g. diameter, clamping force, ...

- Wage calculator

- Machine hour rate calculator

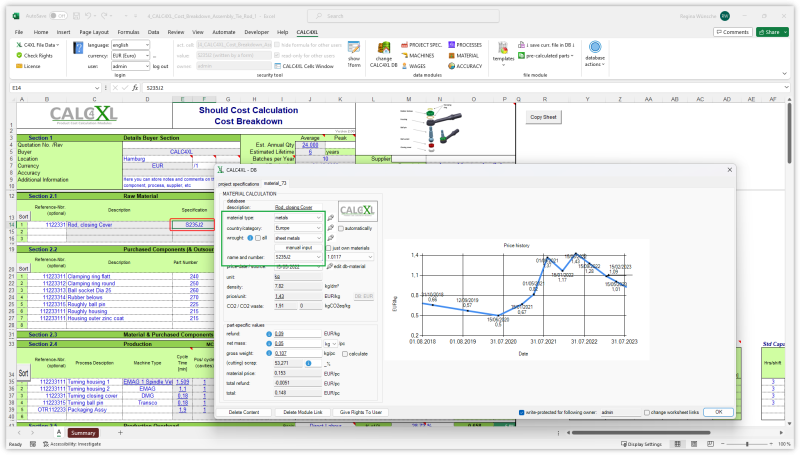

- Material calculator

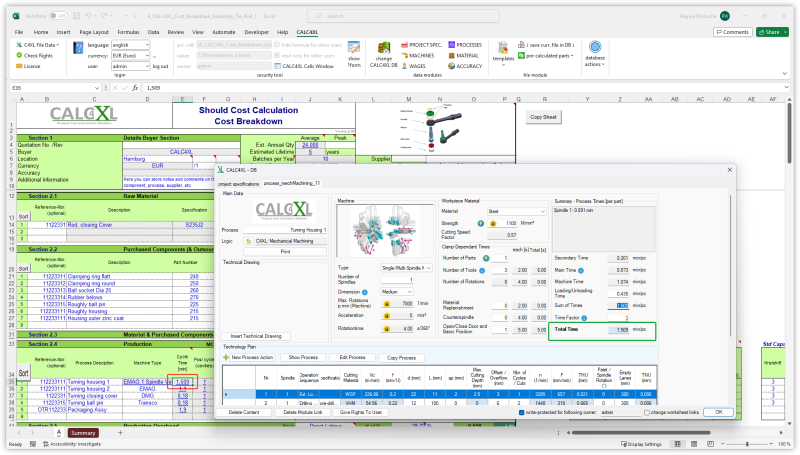

- Use of the CALC4XL manufacturing process calculator for cycle time determination

- injection molding

- die casting

- laser cutting and welding

- rack goods (e.g. KTL)

- mechanical processing

- ... every month a new process is added

- Complete calculation schemes for components and assemblies

- differentiated overhead calculation

- comprehensible and practice-oriented

- individually adaptable and expandable by your Excel know-how

- pre-calculated components as template calculations

- just adapt the pre-calculated components to your product

The additional features

- Multilingual (German / English)

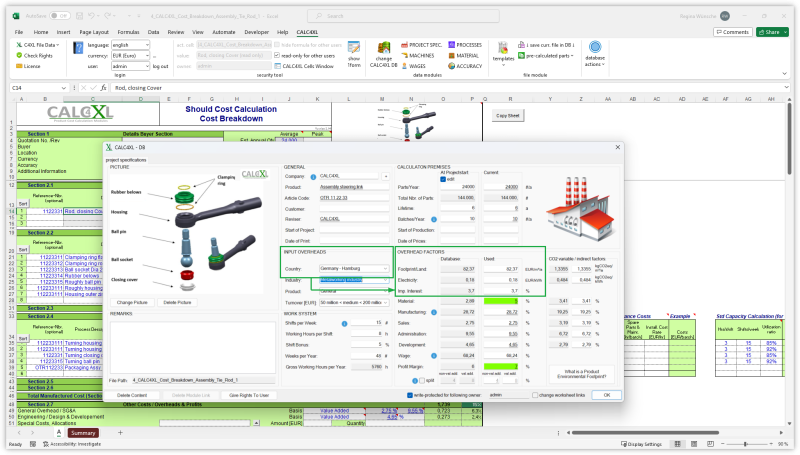

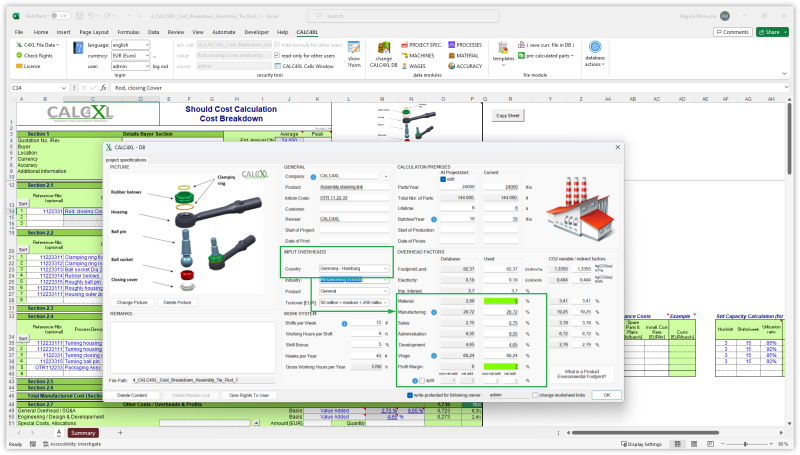

- Fully secured by patented rights and role system (see picture):

- Add as many users as you like with different rights (admin, guest, employee, ...).

- Protect the contents (write-protect) of individual or all Excel cells, so that users with fewer rights cannot modify the cells.

- Hide formulas of single or all Excel cells, so that users with less rights cannot see the formulas.

- The security happens in CALC4XL and therefore cannot be cracked with the common Excel hacking tools.

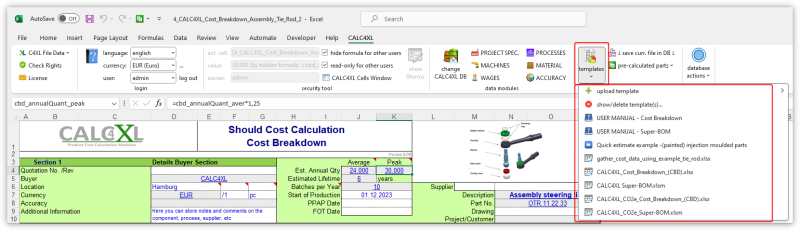

- Company-wide templates through CALC4XL template module (see picture):

- Create secured and thus standardized (Excel) templates for employees, customers, suppliers...

- Use our or your own Excel calculations as templates.

- But also all other files of any file type can be rolled out as templates (xlsm, pptx, docx, ...).

- To do this, simply press "Add template": Everyone accessing the same database can now open and use the template according to their assigned rights.

- Multi-user, offline as well as fully online thanks to the proven Excel and Microsoft infrastructure (Office Online, Sharepoint, ...).

The integration

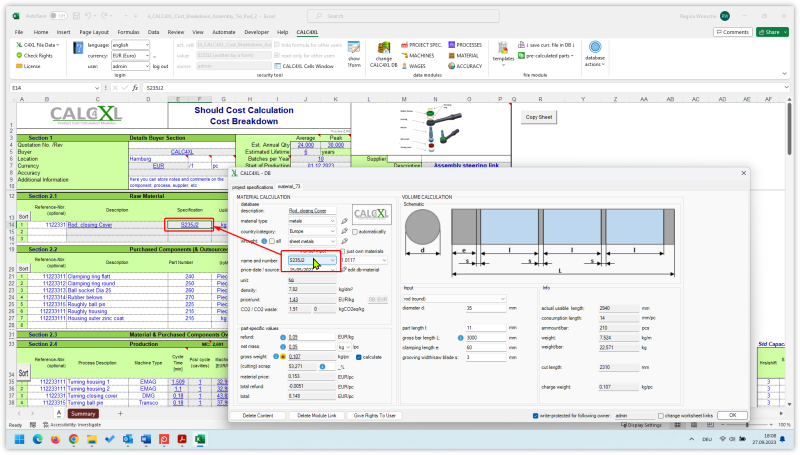

- Fully modularized

- CALC4XL is a complete product cost calculation software, easy to use thanks to the Excel environment and self-explanatory thanks to the sample calculations.

- However, some users only need the expert knowledge of some CALC4XL modules (calculators, data sets). Therefore you can insert all calculators (wage, machine, material, manufacturing process calculators, ...) and each data set (overhead factors, country, machine, material, wage sets, ...) into your own Excel spreadsheets. Almost every value of every CALC4XL form (calculator, data sets) can be linked into an Excel cell.

- A double click on a linked Excel cell opens the corresponding CALC4XL form (see picture).

- Fully customizable

- In the evolution of a cost engineering you will increasingly want to customize your and our Excel calculation templates to your needs. Therefore you can modify all our templates, add and delete CALC4XL modules (calculators, data sets) in your and our calculations. With this modular, customizable solution you are fully flexible - and all this with full security thanks to our template module and our patented rights and roles system.

- Fully integrated

Complete integration into your software landscape via the manifold Excel interfaces, e.g. to:- ERP systems such as SAP, Oracle, Microsoft Dynamics NAV, ...

- database systems such as Access, SQL Server, mySQL, Oracle, ...

- data from the web, from text files and from XML files ...

- ...and many more.

- In addition, the free CALC4XL viewer allows employees and external users without a CALC4XL license to access your calculations. The familiar Excel application thus enables the exchange across all borders up to an open-book calculation.

Industry 4.0

CALC4XL is a dynamic start-up providing a product costing software just for the Industry 4.0 shaping manufacturing, consulting and industrial production:

- Founders are experienced workers in the manufacturing sector who have been shaping the development in manufacturing and accompanied IT for more than 30 years.

- CALC4XL is a low-cost, easy-to-understand mass solution for activating all employees in all departments to digitally connect cross-company action strategies, value chain and product life cycles.

- CALC4XL is a highly customizable software to meet the individuality and constant requirement changes of the Industry 4.0 dynamics.

- CALC4XL global knowledge domain to digitally share benchmark data such as wages, overhead, machinery and manufacturing process computers ensures competitive collaboration.

- Costing 4.0: CALC4XL offers multiple Internet of Things (IdD) interfaces with the interface market leader Excel, so that the Industry 4.0 revolution can lead to digital costing of the entire value chain, in order to exploit cost reduction potentials and ensure your competitiveness in the future.

Be part of it

- We and our costing experts accompany you:

- Accompanying your product cost calculations and cost engineering projects

- Carrying out product cost calculations for you Cross-checking of your calculations by our costing experts

- Tool cost calculation

- Product and potential analysis

- Competitor analyses/product tear-down

- Participation in various training courses and workshops:

- CALC4XL software and overhead costing

- Full-cost engineering setup

- Design To Cost, Design To Value, Design To Market, Target Costing

- Value Stream Mapping, Profitability Analysis, Make Or Buy, Location Analysis

- Product Costing, Bid Costing, Change Costing, Purchasing Negotiations, Supplier Analysis

- Manufacturing Process Time Calculator, New Manufacturing Process Technologies, and much more.

- Become a member of the CALC4XL Costing Expert Network:

- exchange ideas with other cost estimators on our platform, conferences and user meetings

- get connected to costing experts

- offer your services to others

- and participate in the active CALC4XL roadmap

You have questions e.g. about the system requirements - then browse through our FAQs. Here we have compiled a list of frequently asked questions for you.